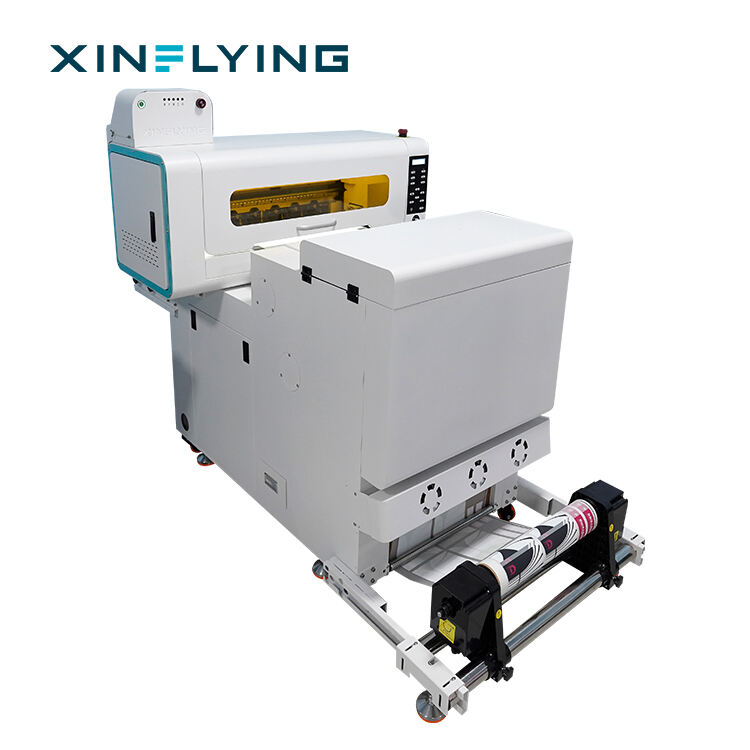

Once you are all familiar with different types of printing, you can ask this question: how has printing changed over the years? Yes, printers used to only print on paper. Paper was the primary method for the dissemination of design and it was used to fold pictures and words into small packets. With the new DTF technology, though, it can also be done on fabric! IVES: This new method of printing is pretty exciting for the printing industry, and it provides all kinds of possibilities for creativity. So, what is DTF? Direct-to-Film means DTF, and you need a special onboard printer with an OEM printer. This is done by first printing your design on a special film. This transfer can then be used to transport the design on to your fabric. Isn’t that cool? Now, let’s look, in detail, at the fabulous advantages of employing OEM printer DTF.

OEM printer DTF is the most suitable for you if you want to produce real fine and robust prints. This technology is developed to create vivid and long-lasting printouts without fading. The special film used in DTF is designed to adhere to fabrics exceptionally well. It stands up to wash and wear, so your designs will continue to look great. No matter if you are printing on a t-shirt, a hoodie or on whatever else wear, your design will stay nice and vivid for a long time. On top of that, the OEM printer calibrates to ensure that your design is printed most accurately. It implies that every little detail of your design will emerge just the way you imagined it!

Transfer paper has long been used for printing on fabric, but with OEM printer DTF, the printing has become a whole new level. When printing with transfer paper, there can be times when, after the transfer, your prints appear dull or faded, and you may not like how they come out. However, with DTF technology, your prints can be bright, bold and colourful! That is because the DTF ink can actually bond better with the substrates, allowing you to have some vibrant results. There are also textile printing sheets, which allows you to print on many types of fabric (approximately cotton, polyester, and a variety of blends). This means that you can design for any type of clothing or other items. To avoid these with OEM printer DTF, you will need to stop using dull and inefficient transfer paper and start printing vibrant and striking images.

As time is play a crucial role in any business so DTF technology saves your time as well as your effort. With OEM printer DTF, you can simultaneously print multiple designs, an ideal tool for extensive printing needs. It helps you work faster and therefore produce more products (as opposed to printing one design at a time). You have fastest orders in no time because the whole process is easy and fast. And because those prints are so high quality, you won’t have to worry about reprinting them due to errors or degradation. This effectiveness allows you to focus on what matters, getting more tasks done, and scaling your business.

Custom clothing printing is a very hot and growing business, and using OEM printer DTF will make you even better. This fantastic procedure will provide your clients with vivid and noise-free layouts for all type of material. This means that you can design unique clothes for all types of event, whether you're printing for an event, a sports team, or a business that needs branded clothes. There is no end to possibilities here! With DTF you can produce more orders and stay on top of your customers demands efficiently and quickly This allows you to expand where your product line can go!

We have local warehouses across United States, Brazil, Indonesia, India, other places. Only you OEM printer dtffor sales of the item. We will assist you logistics transportation costs.

Our after-sales engineers can provide on-site support aid agents with developing their after-sales team. Our engineers speak fluent English are able build OEM printer dtf customer relationships.

XinFlying's 10-person R and D OEM printer dtfteam constantly monitors feedback of our customers to develop enhance our products. You can get a competitive advantage on the market as our agent and take advantage of the technical advantages our products can provide.

XinFlying is one of the earliest DTF OEM printer dtfcurrently enjoys high brand recognition worldwide,specialized digital printing industry over 13 years.This enables you achieve greater success in the sales process。