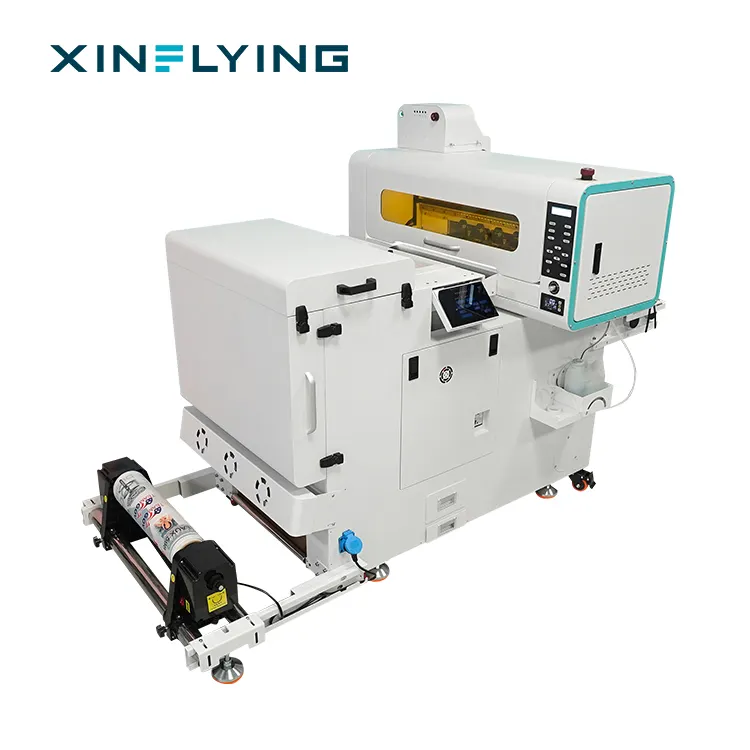

L'objectif ultime dans l'impression directe sur film (DTF) dynamique est d'obtenir des transferts vifs, durables et de haute qualité. Chez Guangzhou Xin Flying Digital Technology Co., Limited, nous savons que votre réussite ne dépend pas uniquement d'une imprimante performante, mais aussi des consommables utilisés. Un aspect essentiel de ce processus est le film PET ou film de transfert. En tant que support provisoire de votre motif, le bon film permet un transfert parfait de l'encre sur le produit final. Ce guide vous présente les types de film PET indispensables et vous donne des conseils pratiques pour choisir le meilleur film PET afin d'optimiser vos impressions DTF A3.

Le rôle du film PET dans l'impression DTF A3

Le film PET est l'acteur secret du procédé DTF. C'est également un polyester transparent et non rigide, recouvert de couches d'encre blanche et colorée imprimées, ainsi que de poudre adhésive thermofusible. Lors du processus de pressage à chaud, cette structure laminée complète cesse d'être liée au film pour s'ancrer définitivement dans le tissu. L'efficacité du transfert, la précision des détails et le toucher final de l'impression dépendent directement de la qualité du film. Un mauvais film peut provoquer des transferts incomplets, des fissurations ou un fini rigide. Le choix d'un film conçu pour fonctionner avec la machine et les autres supports constitue donc la première étape vers une production professionnelle.

Principales formes de PET film à utiliser en DTF

Les films PET ne sont pas tous créés de la même manière. Dans le cas de l'impression DTF A3, les films diffèrent généralement selon le traitement de surface et l'épaisseur. Le film PET enduit est celui le plus courant. Dans ce cas, le revêtement anti-adhérent est un type exclusif qui peut être transféré facilement, entièrement et proprement avec les couches d'encre et d'adhésif. La qualité du revêtement est ce qui fait la différence en matière de transfert, ainsi que du film lui-même, en fonction de la vitesse de production et du rendement. L'épaisseur du film est un autre facteur à prendre en compte. Les films d'épaisseur standard sont très stables et sont généralement utilisés à des fins courantes. Les films plus minces permettent une sensation légèrement plus douce au toucher sur le transfert final, ce qui est souhaitable dans certaines applications textiles. Chez Xin Flying, nous proposons des films PET enduits spécialement conçus pour l'impression DTF A3, avec un revêtement anti-adhérent de haute qualité et une grande durabilité.

Les critères pour cHOISIR le bon film PET

Le choix du bon film PET ne se limite pas à la taille ; plusieurs autres facteurs doivent être pris en compte. Tout d'abord, évaluez la compatibilité : assurez-vous que le film est compatible avec l'impression DTF ainsi qu'avec votre encre et votre poudre adhésive utilisées dans l'imprimante. Ensuite, testez les caractéristiques de décollement. Un relâchement régulier est essentiel pour préserver les détails fins et éviter les pertes. La stabilité thermique du film est également importante : le film ne doit pas se déformer sous l'effet de la chaleur pendant les phases d'impression et de pressage. Considérez aussi l'utilisation finale. Un film permettant une couche de transfert plus extensible peut s'avérer préférable pour des transferts destinés à des tissus élastiques. Lorsque vous expérimentez un nouveau matériau, nous vous conseillons de tester d'abord une petite série afin de vérifier que le matériau fonctionne correctement, adhère bien, et que le résultat final est souple sur la surface imprimée.

Optimisez votre Flux de travail avec le film idéal

Le film PET du bon choix simplifie tout votre processus de production. Un film efficace limite également le nombre d'erreurs lors des transferts, minimise le gaspillage de matériaux et améliore la qualité de vos produits finis. Il permet à votre imprimante DTF A3 de fonctionner à pleine capacité, en produisant des images nettes et des couleurs vives, lot après lot. La collaboration avec un fournisseur fiable tel que Guangzhou Xin Flying Digital Technology Co., Limited vous offre l'opportunité de recevoir des produits de haute qualité en termes de films PET ainsi qu'un service technique qualifié. Nous concevons nos produits pour répondre aux exigences strictes des imprimeurs professionnels, afin de vous permettre d'établir une réputation de qualité et de développer votre activité en toute sérénité.

Vous investissez du temps pour apprendre et choisir le bon film PET, un investissement qui améliore la qualité de votre impression et l'efficacité de votre fonctionnement. Vous pouvez également assurer une utilisation optimale de votre procédé d'impression DTF A3 en tenant compte de la compatibilité, des caractéristiques de décolage et des exigences d'application.

EN

EN

AR

AR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

FA

FA

AF

AF

BE

BE

KA

KA